Providing the most efficient and economical heat recovery solutions

Hoval Plate and Rotary Heat Exchangers: A Perfect Combination of Expert Technology, Cost-Effectiveness, and Versatile Size Options

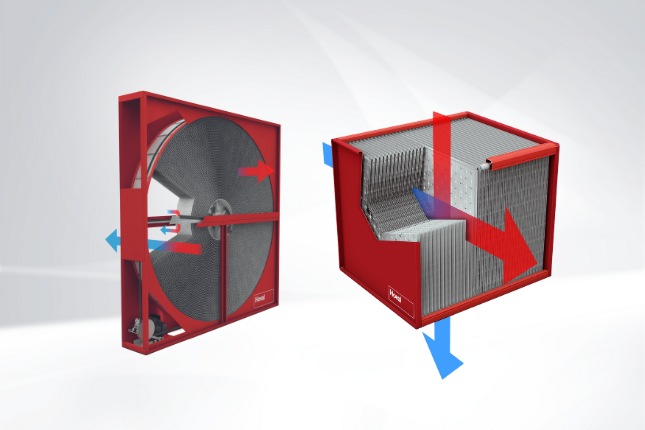

Hoval's cross-flow plate heat exchangers offer exceptional sensible heat recovery efficiency exceeding 80%, outperforming similar products in the market. The compact design of Hoval's heat recovery solutions saves valuable space and costs in your air handling units.

Equipped with patented self-adjusting seals, Hoval's heat exchangers achieve over 70% improvement in sealing performance compared to traditional rigid seals. As the only manufacturer offering calculation software to determine leakage rates, Hoval's rotary heat exchangers enable smaller-sized designs for your air handling units or process systems, leading to cost and energy savings.

We offer customized production tailored to your specific requirements – your cross-flow plate heat exchangers will be manufactured exactly as you need them, eliminating the need for additional bypasses and dampers in your air handling units.

Expert-level technology

As a founding member of the Eurovent Certification Institute for plate heat exchangers in Europe, Hoval's plate heat exchangers boast rigorously certified technical data and exceptionally high sealing performance, providing users with reliable performance guarantees.

Economical and efficient

Not only do they offer high heat recovery efficiency, but the compact cubic design of Hoval's plate heat exchangers also makes them more space-efficient, further reducing the investment costs for users.

Multiple model selection

Hoval's plate and rotary heat exchangers offer a diverse range of sizes to cater to different needs. In terms of plate heat exchangers, they come in a wide variety of lengths and widths, making them suitable for air conditioning systems of all scales. The diverse design of air flow rates allows Hoval's plate heat exchangers to flexibly adapt to various operating conditions.

The most efficient, economical and reliable heat recovery

Leader in efficient heat exchanger

In the field of heat exchange technology, Hoval stands out as an industry leader with its exceptional plate and rotary heat exchangers. These two products not only demonstrate expert-level technology but also offer unparalleled advantages in terms of cost-effectiveness and flexibility, providing users with a diverse range of options.

The cross-flow plate heat recovery system achieves a sensible heat recovery efficiency exceeding 80%, outperforming similar products in the market. The compact design of Hoval's heat recovery solutions saves valuable space and costs in your air handling units. Moreover, the high-efficiency rotary heat recovery system can reach an efficiency of up to 90%.

Furthermore, based on the calculation method of the EU VDI 3803 standard, Hoval can help users optimize their designs to achieve maximum heat recovery with minimal airflow, thereby promoting energy savings in both production and operation.

Excellent sealing and detail innovation

As a founding member of the Eurovent Certification Institute for plate heat exchangers in Europe, Hoval's plate heat exchangers boast rigorously certified technical data and exceptionally high sealing performance, providing users with reliable performance guarantees.

Compared to traditional rigid seals, Hoval's patented self-adjusting seals offer over 70% improvement in sealing performance. As the only manufacturer that provides calculation software to determine leakage rates, the use of Hoval's rotary heat exchangers enables smaller-sized designs for your air handling units or process systems, leading to cost and energy savings.

Innovative Details: The cross-flow plate heat exchanger features aluminum plates with an interleaved, edge-crossed closed design and a stacked structure. The plates have a thickness of just 0.13/0.15 mm.

Rotor heat exchanger structure

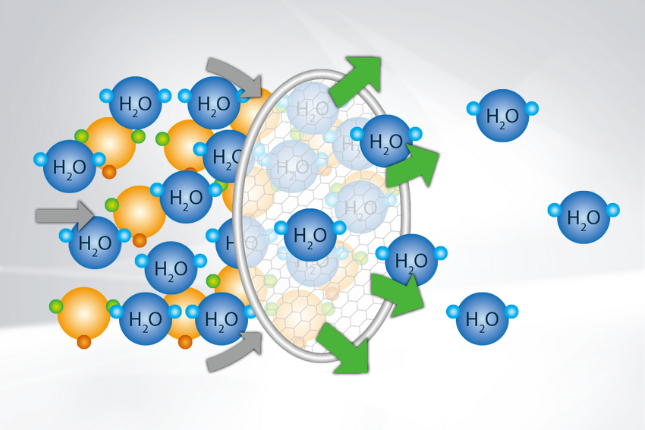

Honeycomb Energy Storage Medium

The energy storage medium consists of double-layered aluminum foil, classified based on the amount of humidity adsorbing material present on its surface. The honeycomb heat storage body offers various options for the height and width of its wave-like structure, allowing for customization according to project requirements to address different needs in terms of efficiency, size, and resistance.

3A Molecular Sieve - Its porous structural characteristics enable "screening" of air components at the molecular level on the contact surface.

Austria

Austria

Belgium

Belgium

Bulgaria

Bulgaria

Croatia

Croatia

Czech Republic

Czech Republic

France

France

Germany

Germany

Hungary

Hungary

Italy

Italy

Liechtenstein

Liechtenstein

Luxembourg

Luxembourg

Poland

Poland

Romania

Romania

Russia

Russia

Slovakia

Slovakia

Switzerland

Switzerland

United Kingdom

United Kingdom

China

China

Corporate Website

Corporate Website

Energy recovery

Energy recovery