Hoval THSD is suitable for high-temperature operating conditions and steam systems.

The Hoval THSD steam boiler series, as an outstanding representative in the field of industrial thermal energy, is widely used in various industrial scenarios due to its superior performance, high safety standards, and excellent maintenance convenience. This series of boilers covers a full range of production capacity needs, from tiny to enormous, with a maximum steam output capability of up to 20t/h, fully meeting the production demands of enterprises of different sizes.

Safety is one of the core values of the Hoval THSD steam boiler. The series strictly adheres to and exceeds Chinese national standards, employing a dual low-water level protection mechanism to ensure that dry burning is effectively prevented under any operating conditions, even for the smallest models.

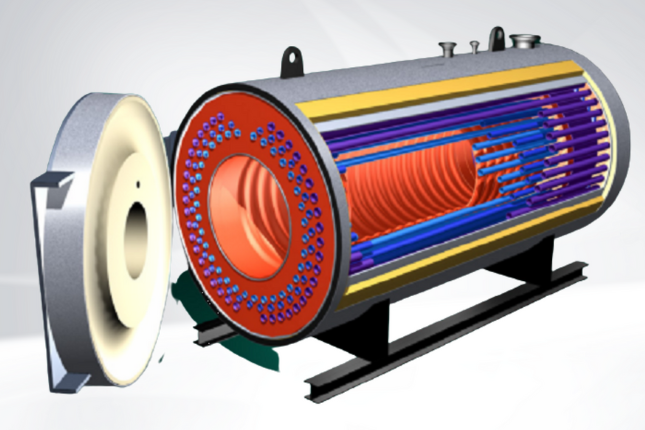

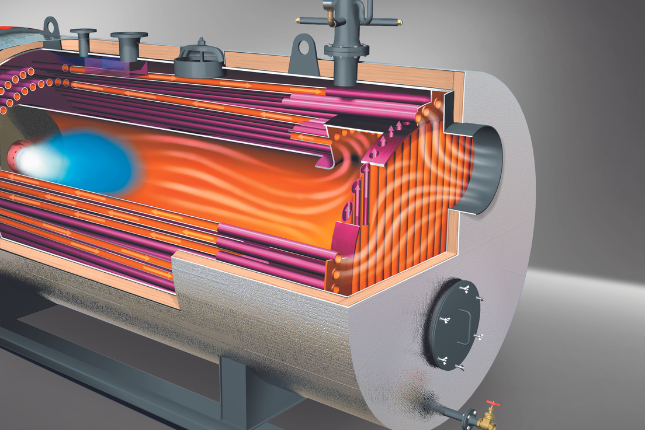

The three-pass integral structure not only enhances combustion efficiency but also significantly reduces emissions of harmful substances such as nitrogen oxides. The specially configured low-NOx burner further controls nitrogen oxide emissions to below 30mg/Nm3.

High energy efficiency

The special wet-back structure, combined with the smooth heat exchange surface of the smoke tubes without turbulence plates, achieves clean and efficient operation as well as high fuel utilization.

High steam quality

The Hoval steam boiler is designed with a robust structure that fully incorporates the concept of durability. The innovative finned tube membrane water wall further ensures operational reliability and efficiency, especially when there are significant variations in steam demand at the load end.

Low pollution emissions

A high-quality steam system can achieve rapid cost recovery through permanent low energy consumption. At the same time, the system complies with stringent environmental emission regulations, thus ensuring your investment in the future.

THSD can be applied to various industrial applications, with high efficiency, long life, low emissions, and the most cost-effective solution.

Easy to maintain and safer

The full range of boilers, with a maximum output of up to 20t/h, features a large furnace door design, facilitated by a specially engineered hinge structure. This allows for the easy opening of the furnace door without the need to disassemble the burner, significantly simplifying maintenance and upkeep. Coupled with the optimized insulation design, the radiation loss through the boiler door is minimized.

Hoval's safety standards significantly exceed those of China's national standards. For instance, the boiler body is equipped with two independent low-water level protection systems, and even the smallest steam boiler is fitted with two safety valves.

Unique design ensures efficient operation

A water-cooled flame tube rear wall (made from finned tubes) increases the heat utilisation and reduces radiation losses in the boiler. As no additional brickwork (fireclay) is required in the flame tube, maintenance and servicing costs are kept to a minimum.

The secondary heating surfaces are smooth and thus very easy to clean. The flue gas tubes at the 2'nd flue gas pass on THSD and THW boiler series are special designed and performed as “spiral rolled” tubes, resulting in low flue gas temperatures and optimum efficiency with compact design.

All Hoval industrial boilers are designed as “natural circulation boilers,”allowing for optimum desludging and draining without the need for external circulating pumps.

THSD 1t/h-20t/h (700kW-14000kW)

Hoval THSD is an industrial steam boiler producing 700 to 14000kW of steam with a working pressures of 10, 13 or 16 bar. The steam boiler can be fired on oil or gas.

Hoval high output steam boilers are made of high quality steel and are distinguished by their solid, robust and flexible design, particularly by their ease of operation, their easy maintenance and an optimal efficiency.

Austria

Austria

Belgium

Belgium

Bulgaria

Bulgaria

Croatia

Croatia

Czech Republic

Czech Republic

France

France

Germany

Germany

Hungary

Hungary

Italy

Italy

Liechtenstein

Liechtenstein

Luxembourg

Luxembourg

Poland

Poland

Romania

Romania

Russia

Russia

Slovakia

Slovakia

Switzerland

Switzerland

United Kingdom

United Kingdom

China

China

Corporate Website

Corporate Website

Energy recovery

Energy recovery